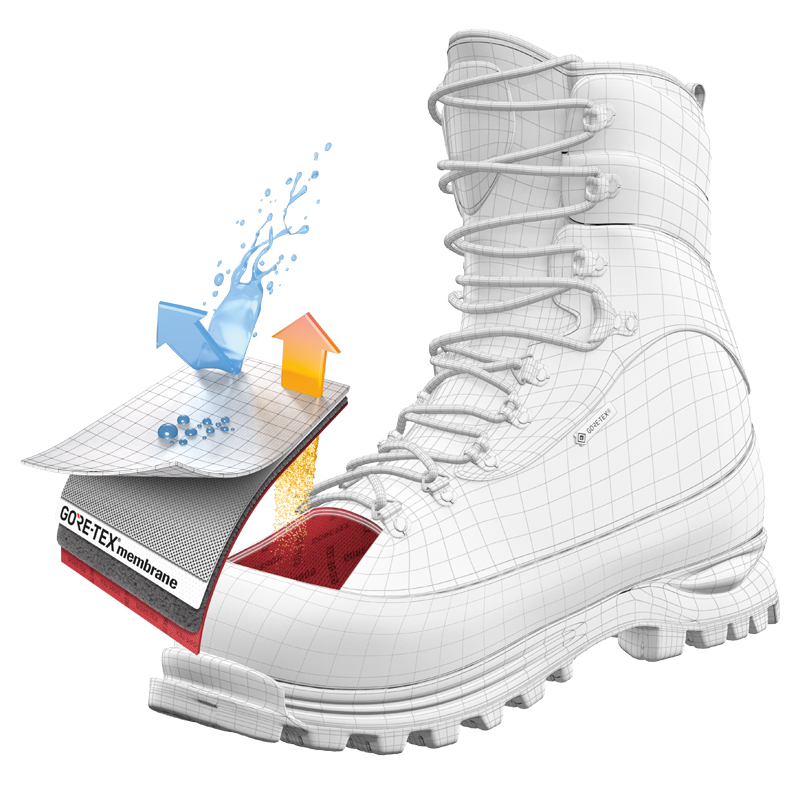

Popular brand that ensures protection and comfort in case of rain, wind or cold temperatures.

Company of excellence that produces rubber soles: guaranteed grip and hold.

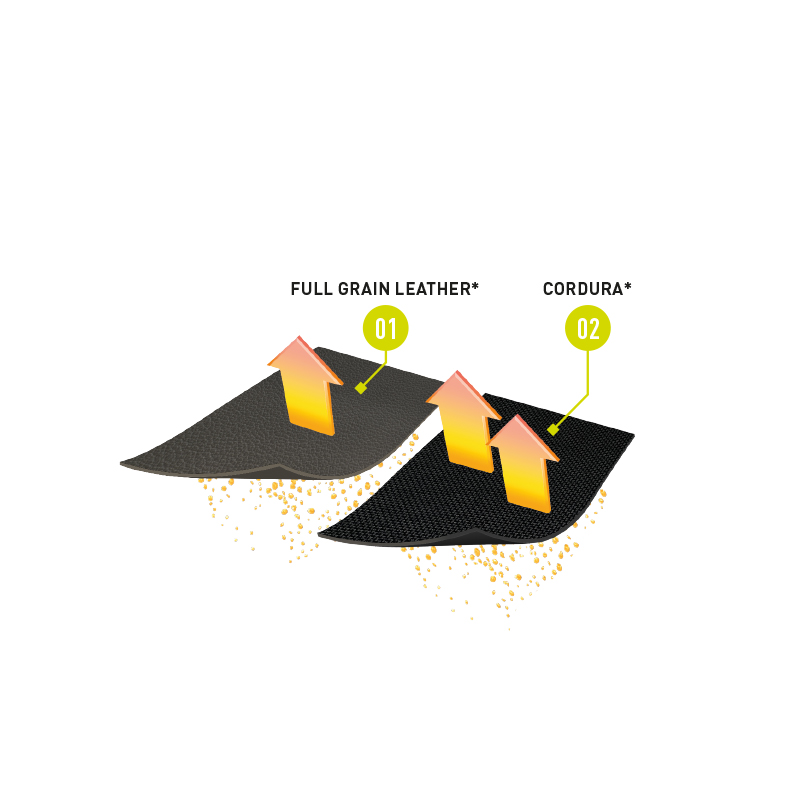

An historical brand. CORDURA makes advanced fabrics that use technologies to protect against scratches, tears and abrasions.

The Perwanger company produces only technical, water-repellent and breathable leather.

Poron XRD Impact material to be incorporated into footwear, an adaptive and wearable impact protection.

Texon Italia is today the only producer in Italy of cellulosic materials for footwear, suitable to satisfy every technical need.

Waterproofing, breathability, resistance and comfort are the characteristics of Dani technical leathers, leader in this high-tech segment.

Conceria Italia is a leader for the quality of the articles produced: one of the reference realities in the sector of the production chain of technical and high quality leathers.

The Heinen leather factory has been producing at the Wegberg site in Germany since its foundation in 1891.